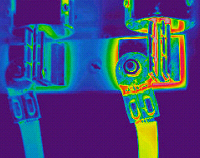

Infrared Scanning is a non-intrusive preventative maintenance inspection used to detect potential points of failure in your power equipment and batteries. Our trained technicians use an infrared camera to produce thermal images of your electrical equipment. Common points of failure like loose connections, corrosion, and faulty assembly can all be detected though this process.

Infrared inspection is used as a key diagnostic tool and is non-intrusive, non-contact, efficient and a cost effective way to detect defects before they cause a major issue. Our process gives you a detailed review of any issues detected, in order for corrective action to happen and before potential breakdowns start. Improve safety, efficiency and maintenance at your facility with proactive tools that work.

This proactive approach to detecting problem areas decreases the risk of equipment failure and ultimately:

*No equipment shutdown is necessary for this process.

Contact one of our experienced sales representatives today. Be sure to see what our clients are saying about us.

Get a quick quote